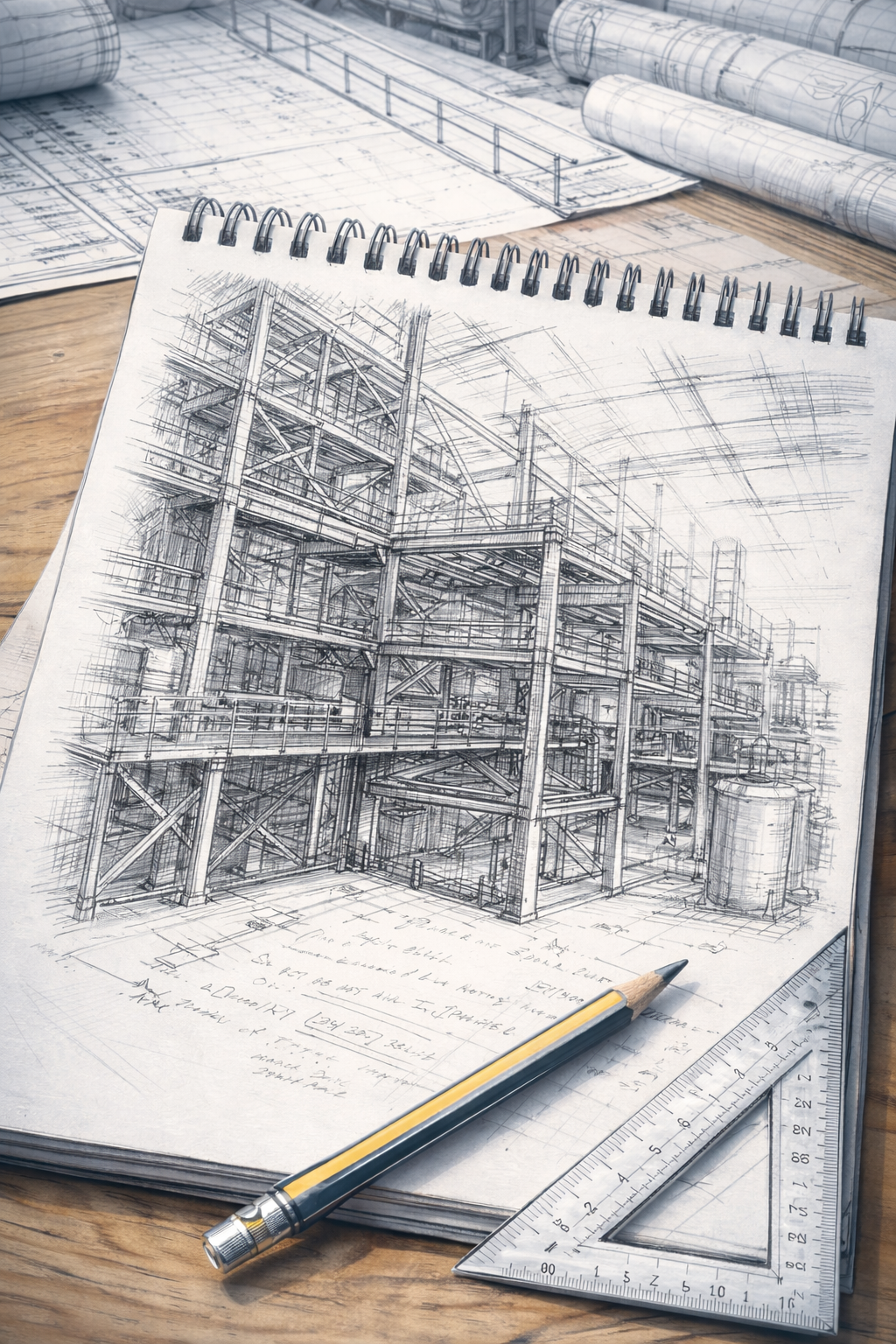

3D Frame Structures in Industrial Applications

Multi-level industrial frameworks with complex load paths

-

3D frame-type structures are commonly used in industrial facilities to support equipment, piping, access platforms, and process-related loads across multiple levels. These structures often resemble building frames but are governed by markedly different loading conditions, stiffness requirements, and serviceability constraints.

Typical applications

Multi-level equipment support structures

Process platforms and pipe racks with floors

Industrial buildings with concentrated and eccentric loads

Structures supporting rotating or vibration-sensitive equipment

-

Multi-level equipment support structures

Process platforms and pipe racks with floors

Industrial buildings with concentrated and eccentric loads

Structures supporting rotating or vibration-sensitive equipment

-

The behavior of three-dimensional frames is governed not only by member strength, but by global stiffness, load path continuity, and interaction between vertical and lateral systems. In industrial contexts, structural response is often controlled by serviceability, deflection compatibility, and load redistribution rather than ultimate limit states alone.

Key governing aspects include:

Continuity and clarity of vertical and lateral load paths

Relative stiffness between frames, floors, and bracing systems

Connection behavior and assumed fixity

Interaction between gravity, lateral, thermal, and operational loads

-

Projects involving 3D frames often present challenges that are not immediately apparent during early design stages. These include:

Concentrated equipment loads applied at locations not aligned with primary load paths

Secondary loads introduced by piping, thermal movement, or operational constraints

Assumptions of diaphragm behavior that are not realized in practice

Sensitivity of global behavior to relatively small modeling assumptions

These challenges require early identification and careful coordination between analysis, detailing, and constructability.

-

Issues in 3D frame structures rarely stem from simple member overstress. More commonly, problems arise from:

Discontinuous or unintentionally altered load paths during detailing or construction

Excessive flexibility leading to misalignment of supported equipment

Underestimation of construction-stage or temporary conditions

Redistribution of forces due to connection behavior differing from analytical assumptions

Such issues may not manifest immediately, but can lead to operational problems, fatigue, or progressive deterioration over time.

-

Rezali supports 3D frame-type structures through a combination of conceptual framing, analytical modeling, and constructability-aware design. Particular attention is given to defining realistic boundary conditions, validating load assumptions, and ensuring that analytical models reflect how the structure will actually behave once built.

Our involvement often includes:

Development and review of global structural models

Evaluation of load paths and stiffness compatibility

Coordination between structural design and supported systems

Design verification and independent technical review

-

Where appropriate, this section may include:

Simplified sketches illustrating load paths

De-identified project photographs

Conceptual models highlighting governing behavior

Captions should focus on what governs behavior, not project identity.

-

Experience with 3D frame-type structures consistently reinforces that:

Early modeling decisions strongly influence downstream outcomes

Serviceability considerations often govern design adequacy

Load assumptions must be actively verified, not inherited

Structural clarity simplifies both construction and long-term operation

These lessons inform Rezali’s approach to both new designs and independent reviews.

-

Many industrial projects combine three-dimensional framing with other structural behaviors. The next section addresses thin-walled structures, where governing behavior shifts from global stiffness to stability and imperfection sensitivity.